Innovative Automated Solutions

We develop the right level of automation for our customers

Experience the ultimate upgrade to your production line with our cutting-edge equipment and software

Unleash unparalleled speed and uncompromising quality that will revolutionize your manufacturing process

100+ years of experience developing mechanical, electrical, electronic, and software systems

Our Products - Targeted Automation

SQUARING TABLE

Unmatched Accuracy, Speed and Flexibility.

Our squaring table is the building block of our wall panel production line. It can be configured for Framing, Insulating, Tacking, and Sheathing Stations, and it integrates with other AMT Robotics equipment, such as the Gen3 Sheathing Bridge, Gluing Bridge, and Panel Flipping Material Handling Station.

GEN3 SHEATHING BRIDGE

The Fastest and most Versatile Sheathing Bridge available.

Our Gen3 Sheathing Bridge allows for up to 8 Heads on a single rail, providing maximum flexibility for dividing up the nailing load among all guns. Screw gun and gluing heads can be added individually or piggyback on existing heads to maximize the versatility of the bridge.

WALL PANEL PRODUCTION LINE

The right solution for you.

Our equipment is designed to improve safety, quality, productivity, and capacity at each stage of theproduction process. We have also designed our equipment to grow with your business. Due to the modular nature of our production elements, you can add features and stations as the demand for your products increases and/or you decide to add more value-added elements to your product offering.

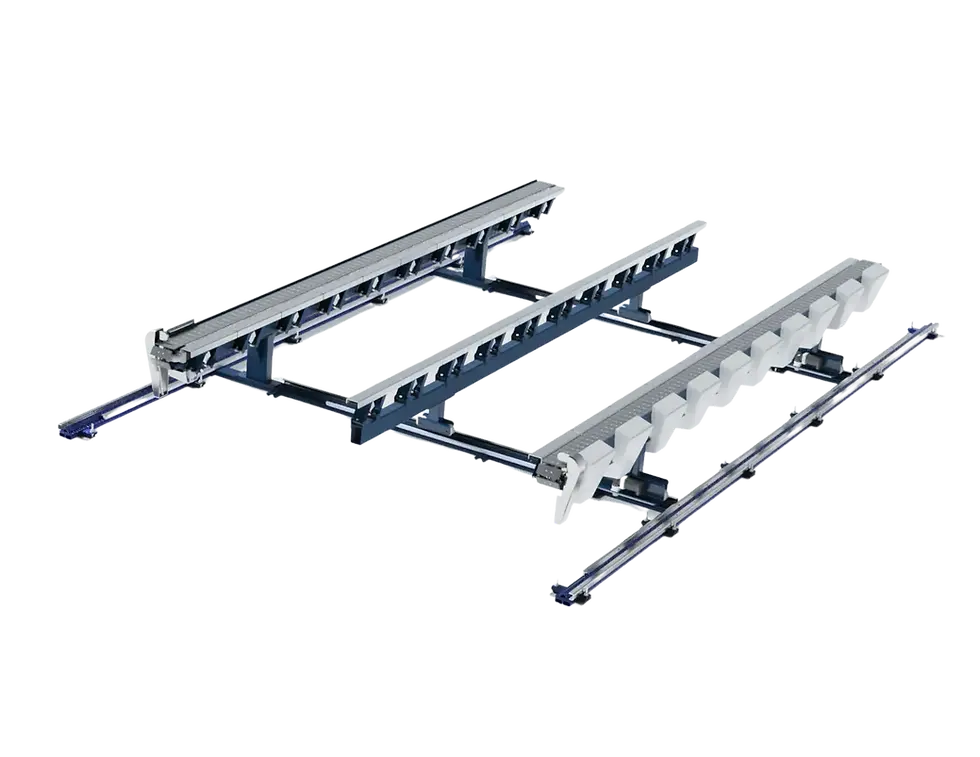

AUTOMATED PANEL FLIPPING AND MATERIAL HANDLING STATION

Flip faster. Build Faster.

Electric motors power our next-generation precision automated panel-handling (butterfly or flip) station, eliminating hydraulics-related maintenance and enabling 20-second cycle times. Infeed powered conveyors transport upstream panels into place for lifting, and outfeed powered conveyors move panels downstream once they are set down again. All functions are automated and stop if any obstacles are detected downstream.

EXIT ROLLER TABLE

Onto the Next – Keep the Line Moving.

This roller table receives a panel at the end of the line when it is ejected from the last station. This additional station provides space for additional value-added activity and time for a crane to stack the panel onto a bundle without slowing upstream stations.

Our customers include leaders in the Structural Building Component Manufacturing Industry.

Our Customers