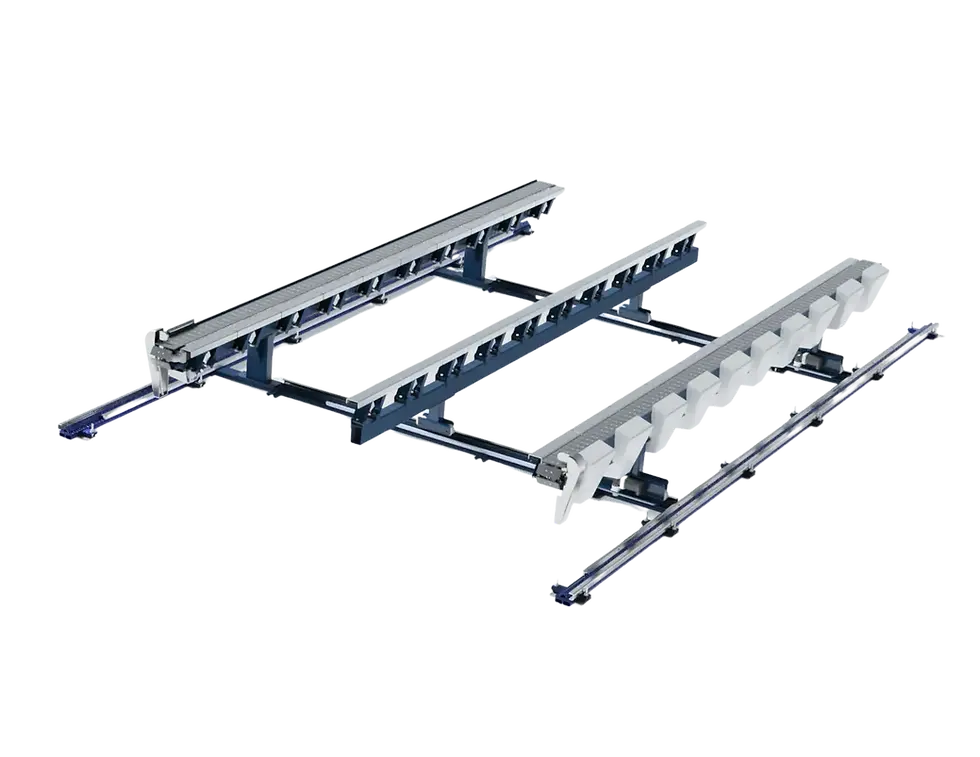

Squaring Table

Our squaring table is the building block of our wall panel production line. It can be configured for Framing, Insulating, Tacking, and Sheathing Stations, and it integrates with other AMT Robotics equipment, such as the Gen3 Sheathing Bridge, Gluing Bridge, and Panel Flipping Material Handling Station.

Unmatched Accuracy, Speed and Flexibility.

Features include powered conveyors, multi-panel queuing, and auto squaring to improve your production capacity, quality, and ergonomics.

The wide power conveyor provides a level working surface, while the panel lifters maintain the panel's location. Upstream panels can continue to move down the line and use any unused areas as buffer zones. The net result is faster cycle times due to less waiting for other stations and less time spent moving panels from station to station. Eliminating extra stations for buffer zones also shortens the line, improving operator efficiency, saving floor space, and reducing the initial cost of the line.

Automated 3 Gun Speed Dollies improve the quality and speed of the nailing and free up the operators for other value-added tasks.

Scissor frames allow oversize panels such as Tall Walls, Rake Walls, and Floor Cassettes to be rotated 90 degrees to fit on the squaring table.

PRODUCT SPECS

-

12’ wide x 20’ long working area (custom sizes available)

-

Powered 7.25” wide Slatted Conveyor

-

Low Profile Tracks

-

Integration with other AMT Robotics equipment

-

Heavy duty powder coated welded steel construction

-

Remote Diagnostics

-

3 year warranty

Optional

-

Centre Rail with Lifters to support studs and blocking

-

Auto Squaring Clamps

-

Multi Panel Lifters for Multi Panel Queueing

-

Swing Gates

-

Scissor Frames for Supporting Tall Walls and Floor Cassettes rotated 90 degrees

-

Automated 3 Gun Speed Dollies

-

Backing for Insulation

-

Stud Straightener (requires centre rail)

-

Under Panel Router (requires centre rail)